Cold chain conditions of meat and dairy products in mexican retail food stores

J. L. Zaragoza-Ramírez 2

P. A. Martínez-Hernández 2

C. C. González-Ariceaga 2

J. L. García-Méndez 3

1 Departamento Zootecnia/Posgrado en Producción Animal, Universidad Autónoma Chapíngo, Texcoco, Estado de México, Mexico

2 Posgrado en Producción Animal/Depto. Zootecnia

3 Departamento de Ingeniería Agroindustrial, Universidad Autónoma Chapingo, México

Abstract

Domestic and international markets show growing concern on food safety and shelf life of perishable animal products that can be affected by cold chain storage conditions in retail food stores. Official Mexican Norms (OMN) determine the official values applied to these animal food products under those conditions. The purpose of this study was to compare cold chain conditions of meat and dairy products among five retail food stores established in a local municipality of Mexico of four national chain-store groups. Temperature conditions of food product surface under cooling for storage of 360 perishable products were measured, and cleanliness related to retail food stores was also monitored by on-site inspection. OMN standards were used as reference in the statistical analysis. Low amount of replications prevented the statistical analysis for cleanliness in retail food stores. Temperature conditions in cooling storage for retail food stores varied (p≤0.05) related to OMN standard. Frequency of surface temperature readings above 4°C of meat products was 2.7%; whilst in milk products 13.3% were above the 6°C. Cold chain on-site related to refrigeration equipment was not monitored due to work regulations of the retail food stores. It was concluded that for some retail food stores there was a need for improvement in keeping cold chain within the standards set by the OMN, specifically for dairy products.

Introduction

Temperature control within the supply chain determines quality and quantity of perishable foodstuff that complies with established standards [1]. Official verifications and own-checking plans of food business operator’s (FBO) of temperature food control is one of the keystones of food safety. Primarily, the responsibility of food safety is for FBO, but food control authorities verify that the handling of food products complies with food safety legislation [2]. Non-compliance of temperature holding and cleanliness and temperatures of refrigeration equipment are also important factors to be monitored, because lack of it may lead to the contamination of food products. Food safety management of cold chain in retail food stores is a key issue in food product selling that require cold holding with the appropriate refrigeration equipment. It must be verified that equipment has been fixed with the proper calibration and the food product is at the correct temperature on it [3]. Similarly, Guiducci et al. [4] pointed out that FBO’s do not always correct the non-compliance and the violation may recur, then more effective measures are required. Morelli et al. [5] added that refrigeration equipment temperature might not always be adequate in retail food stores; although they have their own-check system in operation [3].

Non-compliance recurrence and development of noxious microbiological populations on perishable foodstuff, chiefly due to cold chain problems in retail stores during storage are a threat to consumer health, and also decrease product shelf-life [2]. Own-checking routines of temperature control within a self-planning tailored for each individual store are a basic step towards a sound food safety policy [6]. Lundén [2] found failures in cold holding within retail food stores, whilst Guiducci et al. [4] pointed out that failure in keeping temperature within range is categorized as a critical violation. Steady proper refrigeration demands accurate control of the cold chain in cold holding, since it is a main tool for quality preserving of foodstuffs, and thus its management has a vital role to play in reducing post-harvest losses [7].

Foodstuff losses were related to temperature fluctuations while in storage, increasing these losses as the exposure time to temperature above the recommended standard increased [8]. Abad et al. [9] showed that temperature monitoring is a key factor in keeping a sustainable and unbroken cold chain, and it is related to a temperature controlled supply chain. It should be taken into consideration that temperature requirements differ across food types [10]. Therefore, in retail food stores temperature monitoring and control becomes the most important factor to extend shelf life by maintaining the target holding temperature that assures perishable foods protection against quality loss and wastage. Official Mexican Norms (OMN) [11], [12] provide actual protocols and standards to be applied in the cooling storage temperatures for food products. Thus, the aim of this study was to determine the conditions of meat and dairy products displayed and cleanliness of the surrounding display area in five retail food stores of different national food chains established in a municipality of Mexico to compare them against OMN standards.

Material and methods

Field phase of the study lasted from March to May, 2015 and was carried out in five retail food stores established in a municipality of Mexico; these five stores are of four different national food-chain stores, among them the two largest of the kind. Variables measured were surface food temperature and cleanliness of the surrounding display area. They were measured by on-site-inspection, and an infrared thermometer (Hanna HI 99551-01) was used for surface temperature determination, while cleanliness was visually scored based on a set scale. Meat products surveyed were breaded beef, chicken breast and pork chops; and dairy products considered were fluid milk, Oaxaca cheese type and smoothen yogurt. On-site inspections were done within one week in each of the two months the fieldwork lasted and a total of 360 temperature readings were taken. Statistical analysis was based on frequency of surface temperature readings above the standard set by OMN: 4°C and 6°C for meat and dairy products, respectively [11], [12]. On-site inspection was restricted to the display area as store regulations forbid access to storage areas. Cleanliness was evaluated just one time for each store. Statistical analysis was based on failure frequencies by store and product.

Results and discussion

Taking the 360 temperature readings as a whole, distribution of temperature readings above 4°C were 1.7% and 9.7% for meat and dairy products, respectively; within the range of 0°C to 4°C taking by OMNs; as the optimal range surface temperature, distribution was 21.1% and 20% for meat and dairy products, respectively. Below 0°C distribution was 39.7% and 7.7% for meat and dairy products, respectively (Table 1). Frozen dairy products are not easily accepted by customers that might explain the low frequency of surface temperature below 0°C.

| Meat or dairy product | Temperature level | ||

| <0°C |

0–4°C |

>4°C |

|

|

Breaded beef |

10.6 (38) |

1.7 (6) |

0.3 (1) |

|

Chicken breast |

18.6 (67) |

6.1 (22) |

0.3 (1) |

|

Pork chop |

10.5 (38) |

13.3 (48) |

1.1 (4) |

|

Fluid milk |

1.3 (5) |

6.7 (24) |

4.4 (16) |

|

Oaxaca cheese type |

3.6 (13) |

7.2 (26) |

1.6 (6) |

|

Smoothen yogurt |

2.8 (10) |

6.1 (22) |

3.6 (13) |

Jedermann et al. [13] mentioned that temperature is the factor that can be easily and promptly controlled, and it is also the most relevant and simplest key factor for delaying food product deterioration by implementing an adequate temperature management system. Definitely, keeping perishables quality and safety of products under optimum temperatures results in longer shelf life. Additionally, every perishable food product requires the designated optimal temperature range, and its target is given for a single product that cannot be applied for others if they are stored together in the same cold store area. As a result, chilled product management is much more complex than frozen products [14].

Of the 225 temperature readings done on meat products, six or 2.7% of all meat readings were above 4°C the standard set by OMN for meat products, and of the 135 temperature readings on dairy products 18% or 13.4% were above 6°C the standard set by OMN for dairy (p<0.05). There are several temperature levels for food to suit different types of product groups. These temperature parameters agreed as Smith and Sparks [15] indicated that cold chill is 0°C to +1°C for fresh meat and poultry, and most dairy and meat based provisions; and medium chill is +5°C for some pastry based products, butters, fats and cheeses.

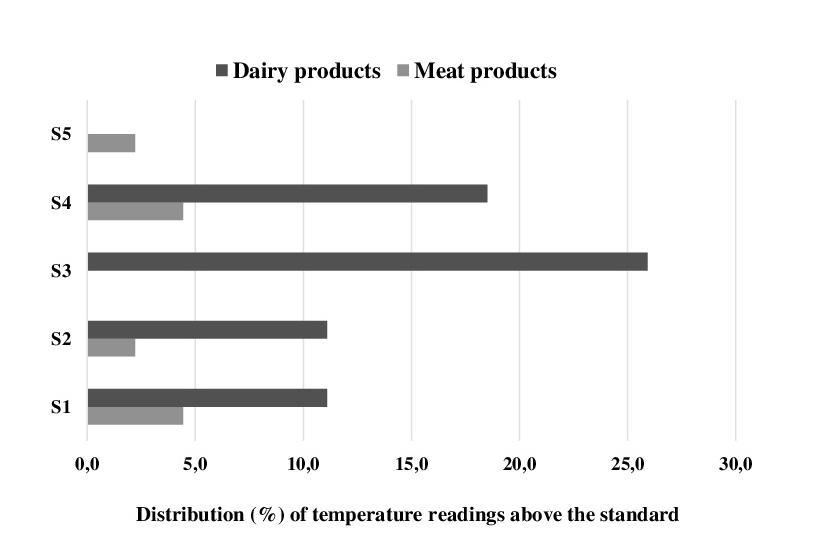

The surface temperature of products revels non-compliance of both types of perishable food in retail stores (p<0.05). Meat products registered non-compliance in four food stores, between 2.2% and 4.4% over 4°C (S1, S2; S4 and S5). In the case of dairy products, non-compliance was also reported in four food stores as well, however, the range was higher, between 11.1 and 25.9 over 6°C (S1, S2, S3 and S4) (Figure 1). The S3 retail store is the only that reported meat products in compliance. It was pointed out that occasionally the 70% of products were above the temperature limits, because poor design of open front refrigeration equipment and poor practices [5]. Regarding temperature compliance, it could show variations on differences between food stores sizes and product groups; however, it could not conclude that any particular store size would perform better [16].

meat (4°C) and dairy (6°C) products by food retail store (S)

It is critical to control temperature and facility manages and processes by protocols. The deviation of optimal temperature settings from the absolute value in a real time environment causes product quality to deviate, and therefore, methods of quality monitoring and assessment are also discussed [14]. Holding ideal temperature is a key factor in order to protect food products against quality losses during cooling storage, it means, that it is necessary to keep under control time and temperature abuse [17]. It is important to consider that the biggest problem for compliance is associated with the lowest temperature limits [18].

On-site inspections were detected non-compliance for cleanliness in four perishable foods. It was found, particularly, that three places out of sight for customers registered the highest percentages (Table 2). Statistical significance differences between food stores were not possible because of low number of stores. Lundén et al. [3] reported the same data made in retail food stores in Finland. However, it was suggested that most reasons are related to lack of knowledge of personal hygiene and equipment cleanliness [19].

| Unclean area | Number of food stores with non-compliance (%) |

| Facilities out of reach of customer | 3 (60.0) |

| Cleaning equipment room | 3 (60.0) |

| Cleaning equipment | 4 (80.0) |

| Service area | 1 (20.0) |

| Self service area | 1 (20.0) |

| Total | 4 (80.0) |

The complexity of supply chain management becomes complex when dealing food products because factors involved, as deteriorating quality and limited lifetime over time, contribute substantially to it [20]. Differences of lifespan and storage conditions are required to keep in consideration for all cold chain products. Humidity and temperature parameters lead to the complexity of cold chain management; therefore, it is necessary to incorporate an adequate setting up a cold chain system [21]. Because compatibility product concern, generally mixed storage of perishables is not recommended in refrigerated storage. These include perceptible concern as colours, due to cross-contaminations, Ethylene production/sensitivity or chilling, and freezing sensitivity [8]. Therefore, as Borghi et al. [22] indicated, allocation of each product to the appropriate refrigerated facilities, such as physical spaces and the fact of creating specific conditions for each variety of product become complex. Cold chain management involves not only temperature monitoring but also quality changes over time. Quality degradation is related to storage itself and the temperature that running on it, as well as various constants, such as activation energy and gas constant [23].

Conclusions

The cooling food products are more susceptible to decay through all food chain management. That is because they require proper temperature controlling, and it becomes a relevant issue in order to improve quality and safety of perishable products. The main factor related in this study was the lack of awareness in these retail food stores. Most of meat and dairy food products are refrigerated on the maximum cooling temperature of compliance. That means, the majority of these products might reduce both, shelf life and quality and safety of them. Some retail food stores could improve the monitoring of the surface temperature of meat and dairy products displayed, and then they could improve shelf life, quality and safety of such products. Research on on-site inspection of cold chain could benefit retail food stores in providing better service to their customers. Thus, it is recommended to continue this type of research into the Mexican food retail stores.

References

[1] Bogataj M, Bogataj L, Vodopivec R. Stability of perishable goods in cold logistic chains. International Journal of Production Economics. 2005 Jan;93–94:345–56. DOI: 10.1016/j.ijpe.2004.06.032[2] Lundén J. Reasons for using enforcement measures in food premises in Finland. Food Control. 2013 May;31(1):84–9. DOI: 10.1016/j.foodcont.2012.09.046

[3] Lundén J, Vanhanen V, Kotilainen K, Hemminki K. Retail food stores’ internet-based own-check databank records and health officers’ on-site inspection results for cleanliness and food holding temperatures reveal inconsistencies. Food Control. 2014 Jan;35(1):79–84. DOI: 10.1016/j.foodcont.2013.06.050

[4] Guiducci GM, Copeland FD, Dorsey T, Edelstein S. A Review of the Food Establishment Inspection Reports in Boston, Massachusetts. Topics in Clinical Nutrition. 2011;26(2):165–70. DOI: 10.1097/TIN.0b013e31821930d0

[5] Morelli E, Noel V, Rosset P, Poumeyrol G. Performance and conditions of use of refrigerated display cabinets among producer/vendors of foodstuffs. Food Control. 2012 Aug;26(2):363–8.DOI: 10.1016/j.foodcont.2012.02.002

[6] Council of the European Union. Corrigendum to Regulation (EC) No 882/2004 of the European Parliament and of the Council of 29 April 2004 on official controls performed to ensure the verification of compliance with feed and food law, animal health and animal welfare rules. Official Journal of the European Union. 2004 May 28 [cited 2016 Feb 03]; L 191. Available from: http://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32004R0882R%2801%29&from=EN

[7] International Institute of Refrigeration. The role of refrigeration in worldwide nutrition, 5th informatory note on refrigeration and food. Paris: International Institute of Refrigeration; 2009 Jun [cited 2016 Feb 6]. Available from: http://www.iifiir.org/userfiles/file/publications/notes/NoteFood_05_EN.pdf

[8] George M, Gormley R. Managing the cold chain for quality and safety, Flair-Flow Europe Technical Manual F-FE 378A/00. 2000 May [cited 2016 Jan 31]. Available from: http://old.vscht.cz/flairflow4/coldchain00.pdf

[9] Abad E, Palacio F, Nuin M, Zárate AG de, Juarros A, Gómez JM, Marco S. RFID smart tag for traceability and cold chain monitoring of foods: Demonstration in an intercontinental fresh fish logistic chain. Journal of Food Engineering. 2009 Aug;93(4):394–9. DOI: 10.1016/j.jfoodeng.2009.02.004

[10] Jobling J. Temperature management is essential for maintaining produce quality. Good Fruit and Vegetables magazine; 2000 Mar [cited 2016 Jan 31];10(10):30-1.

[11] Secretaria de Salud. NORMA Oficial Mexicana NOM-194-SSA1-2004: Productos y servicios. Especificaciones sanitarias en los establecimientos dedicados al sacrificio y faenado de animales para abasto, almacenamiento, transporte y expendio - Especificaciones sanitarias de productos. Estados Unidos Mexicanos: Secretaría de Salud; 2004 Sep 18 [cited 2016 Feb 8]. Available from: http://www.cofepris.gob.mx/MJ/Documents/Normas/194ssa1.pdf

[12] Secretaria de Salud. NORMA Oficial Mexicana NOM-243-SSA1-2010: Productos y servicios. Leche, fórmula láctea, producto lácteo combinado y derivados lácteos - Disposiciones y especificaciones sanitarias - Métodos de prueba. Estados Unidos Mexicanos: Secretaría de Salud; 2010 Sep 27 [2016 Feb 8]. Available from: http://www.cofepris.gob.mx/MJ/Documents/Normas/243ssa1.pdf

[13] Jedermann R, Emond JP, Lang W. Shelf Life Prediction by Intelligent RFID – Technical Limits of Model Accuracy. In: Kreowski HJ, Scholz-Reiter B, Haasis HD, editors. Dynamics in Logistics. Berlin Heidelberg: Springer; 2008. p. 231–8. DOI: 10.1007/978-3-540-76862-3_22

[14] Aung MM, Chang YS. Temperature management for the quality assurance of a perishable food supply chain. Food Control. 2014 Jun;40:198–207. DOI: 10.1016/j.foodcont.2013.11.016

[15] Smith D, Sparks L. Temperature Controlled Supply Chains. In: Bourlakis MA, Weightman PWH, editors. Food Supply Chain Management. Oxford: Blackwell Publishing Ltd; 2007. p. 179–98. DOI: 10.1002/9780470995556.ch12

[16] Likar K, Jevšnik M. Cold chain maintaining in food trade. Food Control. 2006 Feb;17(2):108–13. DOI: 10.1016/j.foodcont.2004.09.009

[17] Ashby BH; United States Department of Agriculture. Protecting Perishable Foods During Transport by Truck, Handbook Number 669. Washington: US Department of Agriculture; 2008 Jul. Available from: https://www.ams.usda.gov/sites/default/files/media/TransportPerishableFoodsbyTruck%5B1%5D.pdf

[18] Lundén J, Vanhanen V, Myllymäki T, Laamanen E, Kotilainen K, Hemminki K. Temperature control efficacy of retail refrigeration equipment. Food Control. 2014 Nov;45:109–14. DOI: 10.1016/j.foodcont.2014.04.041

[19] Little CL, De Louvois J. The microbiological quality of soft ice-cream from fixed premises and mobile vendors. International Journal of Environmental Health Research. 1999 Sep;9(3):223–32. DOI: 10.1080/09603129973191

[20] Bowman P, Ng J, Harrison M, Lopez TS, Illic A. Sensor based condition monitoring. Cambridge: BRIDGE Project; 2009 Jun [cited 2016 jan 31]. Available from: http://bridge-project.eu/data/File/BRIDGE_WP03_sensor_based_condition_monitoring.pdf

[21] Zhang J, Liu L, Mu W, Moga LM, Zhang X. Development of temperature-managed traceability system for frozen and chilled food during storage and transportation. Journal of Food, Agriculture and Environment. 2009;7(3&4):132-5. DOI: 10.1234/4.2009.2425

[22] De Freitas Borghi D, Guirardello R, Cardozo Filho L. Storage logistics of fruits and vegetables: effect of temperature. Chemical Engineering Transactions. 2009 May;17:951–6. Available from: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.491.157&rep=rep1&type=pdf. DOI: 10.3303/CET0917159

[23] Labuza T, Belina D, Diez F. Food Safety Management in the cold chain through "expiration dating". 2003. Available from: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.486.3191&rep=rep1&type=pdf